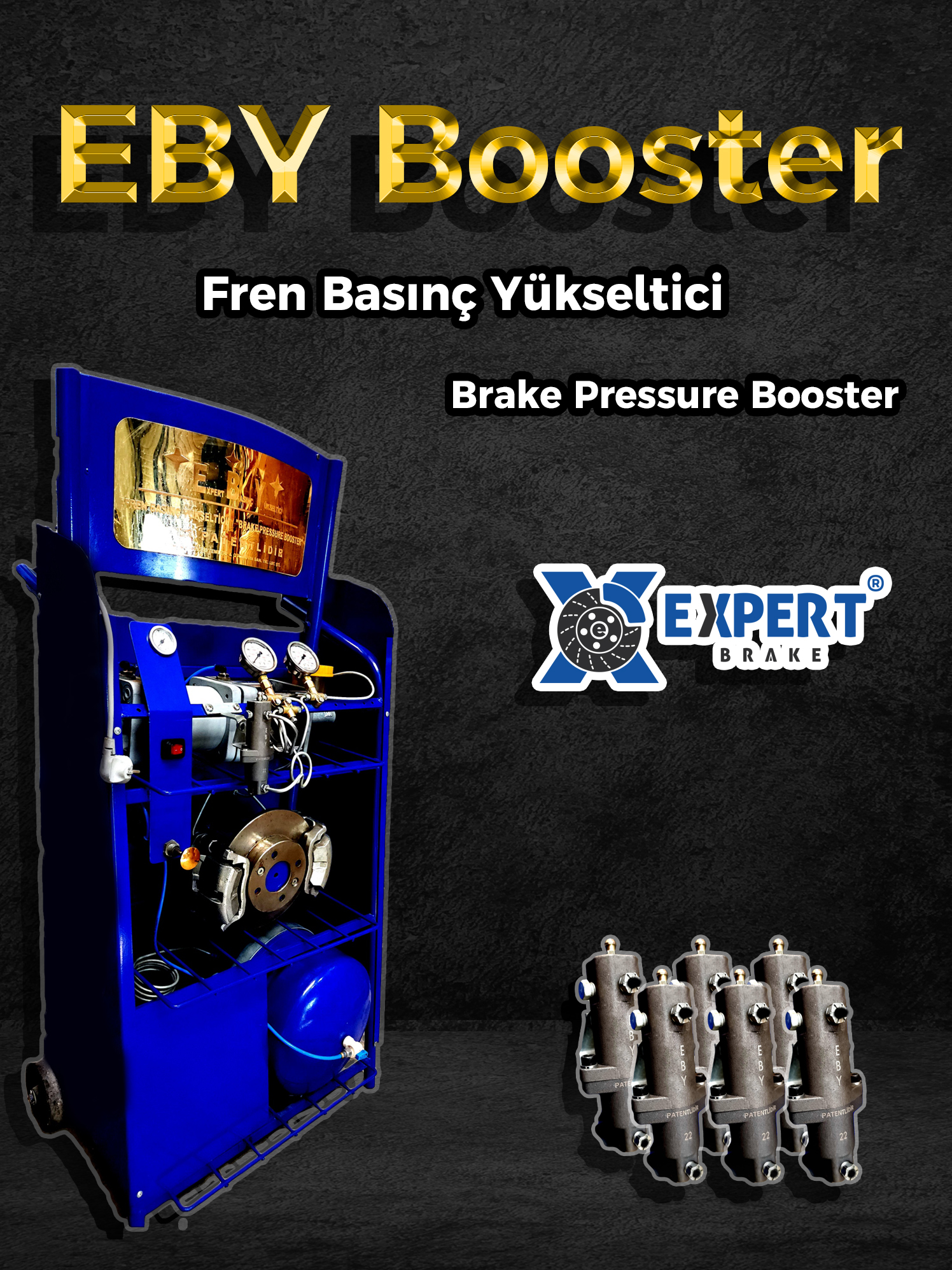

OUR PRODUCT IS A PRESSURE BOOSTING UNIT THAT ELIMINATES THE NEED FOR WESTINGHOUSE / BRAKE BOOSTER / HYDROVAC PRODUCT, ESPECIALLY IN ALL NEW GENERATION ELECTRIC VEHICLES OR INTEGRATED INTO THE SYSTEM FOR A MORE POWERFUL BRAKE SYSTEM AND ESPECIALLY ACTIVATED IN SUDDEN BRAKING, INCREASING BRAKING POWER.

WHY EBY?

One of the most important components of vehicle control mechanism is brakes. The brake system alone gains functionality with the combination of many sub-units. The brake piston, called the brake master cylinder, which is one of the important parts of the braking action, has its own special task and working principle.

Today, in vehicles powered by fossil fuelled engines and electric motors, hydraulic fluid systems are mostly used for braking. When the driver wants to stop the vehicle, he presses the brake pedal and the hydraulic fluid starts to pump, activating the pressure pistons.

The pistons, in turn, push the braking devices according to the type of disc or drum type brakes, compress the brake disc and perform the function of stopping or slowing down the vehicle. In summary, the brake master cylinder/piston is the part that pushes and compresses the braking devices in disc or drum vehicles with pressure from the hydraulic fluid.

The brake systems in vehicles have a Westinghouse structure, also known as a brake booster or hydrovac. Westinghouse is used to increase the brake force and soften the use of the brake pedal. From a general point of view, it is used in vehicles as a strengthening part. The use of Westinghouse product in vehicles is a very useful system for sudden deceleration of vehicles. It enables the vehicle to take precautions against possible accidents and to obtain the ability to brake without forcing the driver. At this point, westinghouse and brake pedal work together.

Air pressure (suction / negative pressure) is required for the westinghouse / brake booster / hydrovac system to operate in vehicles, and the system is operated with negative air pressure generated by a vacuum motor with the power to be taken from the vehicle engine and / or battery. Therefore, an additional energy is consumed from the vehicle engine for the operation of the Westinghouse system.

Although the energy consumption of the vacuum motor that operates the westinghouse/brake servo/hydrovac system in vehicles powered by fossil fuel (diesel, petrol) engines is not paid much attention, the energy consumed in the use of brakes is of great importance, especially in new generation vehicles powered by electric motors. In electric vehicles, it is very important to minimise energy consumption for reasons such as long range, longer use of the battery, etc.

In all vehicles with fossil fuel and/or electric westinghouse/brake servo/hydrovac system, additional requirements are needed in the brake system to provide high braking power in case of possible failure in the hydrovac system.

Our Pressure Booster unit is a method of controlling the hydraulic pressure in the brake cylinders by using a solenoid or piezoelectric push-pull actuator controlled by commands from the brake control unit in wheeled vehicles. Compared to the known methods, the method, which enables high-speed control of the hydraulic pressure in the brake cylinders, allows the pressure in the brake cylinders to exceed the pressure value created in the brake centre when necessary.

As Uzman Fren Sistemleri, our company, which is the solution point for brake systems, has developed this product to provide energy saving especially in electric vehicles. To eliminate the need for westinghouse / brake booster / hydrovac according to the vehicle to be used (engine type, power, etc.), to increase the braking power by being integrated into the brake system and activated especially in sudden braking, to increase the pressure of the brake fluid and thus the pressure applied to the braking devices (drum or disc).

Janet Lopez